Nangona iphucuke ngakumbi ngokubhekiselele kumgangatho wemveliso kunye nokuziqhelanisa nemveliso xa kuthelekiswa neendlela zokufaka kunye nokufaka ibrazing, kusekho iziphene ezininzi ekusebenzeni kakuhle kotshintshiselwano lobushushu kunye nokuthintela ukuqokelelwa kothuthu kwiityhubhu zefinned ezidityanisiweyo rhoqo ngenxa yezizathu ezifana nobunzima bokudityanisa phakathi kweengcambu zeetyhubhu zefinned ezidityanisiweyo rhoqo kunye nemingxunya eengcambu.

Ityhubhu egobileyo luhlobo lwento yokutshintshiselana kobushushu. Ukuze kuphuculwe ukusebenza kakuhle kokudluliselwa kobushushu, umphezulu wetyhubhu yokutshintshiselana kobushushu udla ngokwandiswe ngokongeza amaphiko ukwandisa indawo yangaphandle (okanye indawo yangaphakathi) yetyhubhu yokutshintshiselana kobushushu, ukuze kufezekiswe injongo yokuphucula ukusebenza kakuhle kokudluliselwa kobushushu, ityhubhu enjalo yokutshintshiselana kobushushu.

Njengento yokutshintshiselana nobushushu, ityhubhu egobileyo isebenza phantsi kweemeko zegesi yobushushu obuphezulu ixesha elide, njenge-boiler heat exchanger enetyhubhu egobileyo kwindawo enzima, ubushushu obuphezulu kunye noxinzelelo kunye nomoya ongcolisayo, nto leyo efuna ukuba ityhubhu egobileyo ibe neempawu zokusebenza eziphezulu.

1), Ukuthintela ukugqwala

2), Ukuchasana nokunxiba

3), ukumelana okuncinci koqhagamshelwano

4), Uzinzo Oluphezulu

5), Amandla okuqokelelwa kothuli

Iingenelo zeephini ezijikelezayo zentsimbi engagqwaliyo eziweldiweyo nge-laser.

1. Ngokusebenzisa iteknoloji yokuwelda ye-pulse laser, ukuwelda okujikeleze isiqwenga kugqitywa ngaxeshanye, kwaye izinga lokuwelda lesiqwenga setyhubhu lifikelela kwi-100%.

2. Ukuwelda nge-laser yindibaniselwano ye-metallurgical, amandla okuwelda kweshiti yetyhubhu anokufikelela ngaphezulu kwe-600MPa.

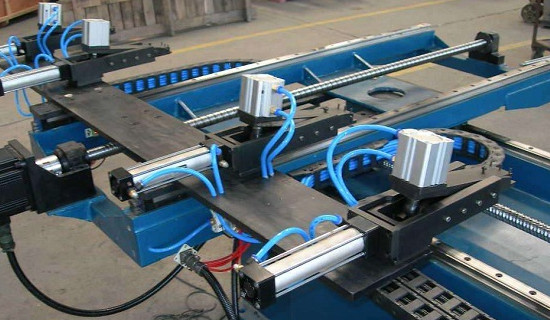

3. Umatshini wokuwelda we-laser wamkela inkqubo yokuhambisa i-servo, ukuchaneka kokuhambisa kunokufikelela kwinqanaba le-Kumi.

4. Umgama phakathi kwetyhubhu yokuwelda yelaser unokuba yi-≤ 2.5mm, indawo yokusasaza ubushushu kunetyhubhu yokuwelda ephindaphindayo (umgama wetyhubhu ≥ 4.5mm) inyuswe phantse nge-50%, izinto ezisetyenziswayo zincinci kwindawo nganye, zinokunciphisa kakhulu umthamo we-heat exchanger.

Ixesha lokuthumela: Septemba-30-2022